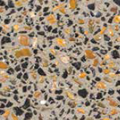

Exposed Aggregate

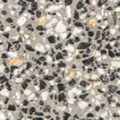

Exposed aggregate finishes by definition, are when the aggregates (the stones and/or sands) near the surface of the substrate are revealed; these components would otherwise be concealed by a thin layer of cement paste and remain unseen. Exposed aggregate concrete is great for paths and driveways. Choose from natural textures of exposed soft river stones and crushed quarry stone, available in a wide range of colours.

How is the Exposed Aggregate texture coloured?

There are various ways of producing an exposed aggregate concrete finish including; water washing, abrasive blasting, acid etching & stencil blasting. The most common technique for producing exposed aggregate concrete finishes is via the "water wash off technique". This technique removes the cement matrix at the surface of the concrete slab via brushing & flushing the surface with water soon after the poured concrete has stiffened.

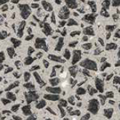

Colouring the Concrete Matrix

The cement matrix (cement, water & sand) between the course aggregate particles in a standard expose mix is grey. This matrix can also be coloured in a number of ways to provide a more stylish effect via the application of mineral oxide pigments, chemical stains, dyes, tints and coloured sealers.

Concrete Surface Set-Retarders

The use of water based surface set-retarders are commonly used in the water wash off technique and are developed specifically to slow the setting time of the surface of the slab to a predetermined depth, without affecting the set of the mass of the concrete. Retarding the surface enables the concrete to bear the weight of the placer without leaving indents in the concrete & allow a more even exposure of the aggregate matrix.

Applications / Use

How much texture can be created in the Concrete?

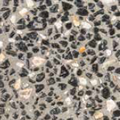

The maximum exposure recommended is 1/3 for the aggregate or particle size. This is to ensure a sufficient depth of the aggregate is embedded into the concrete for an adequate bond.

Finishing and Sealing Exposed Concrete

An acid-wash treatment is usually necessary to remove any fine cement film left on the surface of the concrete & after the exposing; this is highly recommended prior to sealing.